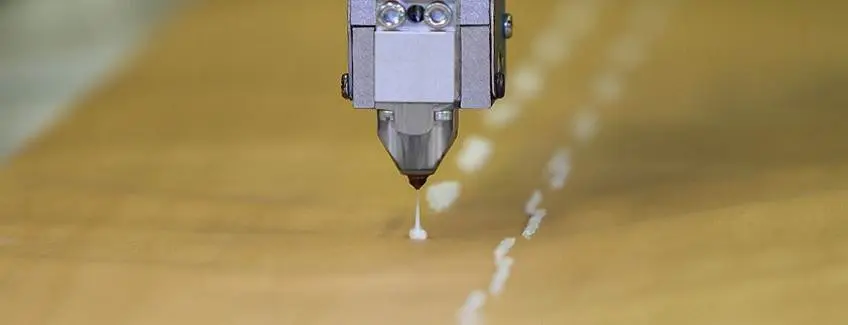

Are you looking for a reliable and dependable of hot melt adhesives supplier? Then you don’t have to look any further! In this article, we are going to take you through a step-by-step selection of the best supplier for your distinct needs.

It becomes an important decision to choose the right adhesive supplier so that the packing operations should be correctly done with a profit. The quality of adhesives used affects the strength of the pack as well as the whole packing process. Thus, it is, therefore, important to team up with a supplier who would be providing the best adhesives and understands your specific needs.

It is very hard to select a proper supplier because of the great number of options. The choice of an appropriate option depends on several things and ranges from customer service to production capacity, product quality, and performance. You may just make the right choice if you well understand what package you need and can evaluate the vendors with their experience, standing, and knowledge in the field.

Regardless of your need-specific adhesive property, specialized packaging solution, or world-class technical support, the success of your packaging operations generally depends largely on your ability to choose the right hot melt adhesive supplier. Read on for insightful guidance and useful tips which will guide you in your selection of the right partner to work on your packaging needs.

Importance of choosing the “right” adhesive supplier

One of the most important decisions made by a packaging company is the choice of adhesive supplier. Other factors, including product safety and shelf life, which are critical to the overall performance and integrity of the package, depend on the adhesive used. The wrong choice of supplier can lead to several problems, including poor adhesion, failed packaging, manufacture delay, and increased costs.

A hot melt adhesive supplier therefore is key to ensuring the successful completion of packaging. The quality, reliability, and knowledge of a supplier may influence the effectiveness and efficiency of the packing procedures significantly. A supplier can optimize the operations by providing technical assistance, possible customization, and fast delivery along with constantly providing high-quality adhesives which particularly meet your needs.

It takes much time and hard work to source the best hot melt adhesive supplier, but the payoff of doing it right might be well worth it. Working with a supplier who understands exactly what you specifically need, giving you an excellent service support can help streamline your packaging procedures, cut wastage and distruptions, and ultimately give the benefit to your clients with an improved product. A good adhesive supplier will also help you get ahead of the pack in the highly competitive packaging industry and secure your market position.

Factors to consider when choosing the hot-melt adhesive supplier

While finding the appropriate hot melt adhesive supplier, there are various factors one needs to consider. Such factors can guide you on your evaluation process and make a decision that fits your business objectives and packaging requirements.

A big factor to be considered is the quality and reliability of the glue supplier. Look for a supplier who has a record of manufacturing high-quality products and consistently delivers. Study their certificates, their quality control procedures as well as their manufacturing process to be assured that it strictly adheres to the legal and industrial standards. A good supplier ensures that their adhesives always meet your specifications and function as desired through a robust quality management system.

Also, customer satisfaction and the reputation of the supplier should not be forgotten. When finding out how reliable and responsive one company is, pay attention to their reputation in the field, clients recommendations and comments, and reviews. If someday you need packaging stuff, that supplier with a good reputation in quality, customer care, as well as on-time delivery, will likely be a trustworthy partner in the deal.

Range of products offered by the supplier

Opt for a products of hot melt adhesives supplier who can provide you with a diverse range of solutions, including, when appropriate, customized formulations tailored to your packaging-specific needs. This may include special forms for various surfaces or applications and adhesives in a number of viscosities, melt points, and tack qualities.

Such a strong portfolio of products by the supplier can thus facilitate greater personalization and greater flexibility, enabling you to select the optimal adhesive for your packaging needs. It may help reduce the need to purchase adhesives from numerous suppliers and make product performance better and more streamlined the packaging operation.

Customization options and technical support

In general, customization and technical support are essential to the packaging industry for its business success. Customized solutions combined with informed advice from the supplier should therefore be part of your choice of hot melt adhesive supplier.

Determine if the supplier can provide specialty formulas, packaging, and delivery options to meet your exclusive requirements. An innovative supplier who can work closely with you to understand your problems and devise creative solutions might be a treasure in streamlining your processes of packing.

Not to forget the technical know-how and support, of course. A really good team of technical experts which can guide you on the choice of adhesive, application and repair can be very helpful to you in achieving your targeted levels of performance and efficiency in your packaging processes.

Customization, along with technical support, ensures that the business wins in packaging industries. The ability of a hot melt adhesive supplier will also be critical in terms of offering customized solutions or consultative advice to your specific needs.

Choosing the Right Supplier for Customized Packaging and Adhesive Solutions

To meet your needs, find a supplier that can deliver the right custom formula, packaging, and shipping option. When looking for a partner in streamlining the packing process, a developing supplier that will collaborate closely with you to understand your issues and create innovative solutions will be a great asset for your business.

Depending on your individual needs for packaging, a supplier should be in a position to formulate an off-the-shelf adhesive with a specific viscosity, melt point, or tack profile. They may also have specific packaging applications for convenience in applying glue, applicator devices, for instance, or specialty containers.

Apart from the matter of customization, another important consideration related to selection is technical assistance and experience by the supplier. A competent group of technical specialists who can provide guidance concerning the adhesive choice, use, and troubleshooting can be of enormous help to you to deliver the needed level of performance and effectiveness in the packaging processes.

You should select a supplier that would be in a position to offer you full technical support that goes beyond on-site training and troubleshooting assistance to occasional advice on how best to use and store adhesives. This level of support can help you assure the consistency of quality on your final products, allow you to streamline your packaging process efficiently, and minimize down times.

You will be able to vary your hot melt adhesive solutions to best serve the needs of your packaging, maximize productivity, and deliver the best possible result for your customers by working with a hot melt adhesive supplier that is able to provide technical assistance and customization options.

The quality and reliability of the supplier

When selecting a partner for your packaging needs, it’s the quality and reliability of your supplier of hot melt adhesives that are of prime importance. A reliable supplier carrying a history of good-quality products and dependable service can be the difference between a packing operation running smoothly versus one with problems.

When evaluating the dependability and quality of your supplier, you need to consider their manufacturing procedures, quality control systems, and relevant industry certifications. A supplier with a proper quality control system means the adhesives you purchase from them are going to meet your standards on a regular basis and do what you want it to do, thereby minimizing downtime at the end of the packaging line and costly downtime.

Client satisfaction and the reputation of the supplier must be considered also. To analyze whether a particular company is reliable or responsive, examine the industry reputation, client endorsements, and reviews. A supplier who is reliable and has a great reputation for quality, customer service, and on time will likely be your best bet for packaging needs.

Determining the samples and properly testing the goods of the hot melt adhesive supplier are the two ways with which one can evaluate quality and reliability of that supplier. This will make you know the effectiveness of the adhesives in your specific packaging environment and ensure it meets your requirements in diverse various aspects, for instance, the characteristics of application, strength of the bond, as well as heat resistance.

By selecting the right reliable and quality hot melt adhesive supplier, you can ensure the success and effectiveness of your packing operations, the lesser chance of possible failure occurrences, and a more consistently better quality product to deliver to your customers.

Variety of adhesive items the provider provides

Consider the variety of goods that the adhesive supplier makes. A supplier offering a wide range of adhesives will be much easier to help you pick the best glue for your specific packaging needs and applications.

Seek a hot melt adhesive supplier who can offer a wide selection of hot melts with differing viscosities, melt points, and tack characteristics. By selecting the most compatible adhesives for the substrates you handle, the application techniques you use, and the conditions under which you package your products, you can simplify your packaging operations and optimize the performance of your packaged products.

Consider the supplier’s ability to provide custom adhesive formulations along with its extensive product offerings. Some packing applications may require specialized adhesives with higher heat or chemical resistance or specific bonding properties for challenging substrates. A supplier that can formulate custom solutions to your specific needs can be an important partner in the solution of your specific packaging problems.

Third, look for a supplier that can offer a variety of adhesive packaging options- such as different applicator systems, container sizes, and delivery types. This type of flexibility may reduce your packaging complexity and spare you long-time headaches about the headache of purchasing adhesives from many different suppliers.

Working with a supplier of hot melts that has a superior portfolio, thus offering numerous top-of-the-line items to your company’s packaging operations, will help ensure your operations have the adhesive solutions your business needs to operate at its best, to work more efficiently, and to steadily produce better results.

Cost effectiveness

While hot melt adhesive supplier selection does provide for pricing and cost-effectiveness, quality and dependability must be first. Balancing your packaging business’s budget and the need for top-tier adhesives is a vital necessity to maintaining profitability and competitiveness.

Use the per-unit cost of the glue as well as the total cost-effectiveness of the supplier’s offerings to judge the pricing that they provide for hot melt adhesive. Look for a supplier who can give you competitive pricing without compromising the effectiveness or quality of the product.

Consider the supplier’s pricing policy plus any potential rebates or volume discount options that they can offer. Some suppliers will give volume-based price breaks, or bulk discounts and tiered pricing based upon what quantity of adhesives you may be purchasing. This can benefit you in managing your budget adhesives costs efficiently.

Assessing of Cost Effectiveness and the Relationship with Suppliers of Adhesives to Packaging

Consider the direct cost of the adhesives, plus charges from the supplier for ancillary services such as delivery, technical assistance, or customization. If your supplier has a wide range and at reasonable prices with supplementary services, then they can be a good partner in controlling your packaging costs.

Consider also the long-term cost efficiency of the products being offered by your supplier. Although that would save you the dough up front, you’ll need to invest more for these adhesives that would be effective, consistent, and remove waste and downtime in packing with their adhesives. Even though the cost per unit is a bit more expensive, it would prove to be economical in the long run to stick with a supplier who can deliver consistent high-quality adhesives for optimum use of your packaging efficiency.

But by reviewing the cost and financial feasibility of the different hot melt adhesive suppliers, you might find the best partner who has high benefits and maintains your competitiveness in the packaging industry.

Delivery and logistics

Consider the delivery and logistical capabilities of the hot melt adhesive supplier when you decide on your packaging partner. In point of fact, the efficiency and effectivity in packaging processes have more to do with adhesives’ reliability and timely supply than anything else, which ensures at all times that there is always a supply for the demand for your product.

Also, in considering suppliers, analyze their order fulfillment processes, transportation network, inventory management, and other systems and check if a supplier is able to deliver adhesives really on time as needed, and when you want to use them within regular or emergency service.

Effective and flexible delivery options are also essentials. To avoid or minimize production slowdowns and out-of-adhesive stockouts, a smart supplier must offer varied modes of deliveries, such as direct-to-site delivery, just-in-time delivery, or expedited shipment in order to let you use your inventory management.

You also need to determine whether the supplier can take care of any special shipping or packing needs you may require. This could include use of specific packaging to ensure the integrity of the products during transit and even the control of temperatures through the transport of temperature-sensitive adhesives.

With a good logistical infrastructural backbone in place with your supplier who is committed to delivery on time, packaging at your workplace is more than likely to go much smoother and effectively. You are free to focus on other sides of business but will be confident that the adhesive supply for your company will be reliable and consistent without any form of interruption when you work with a supplier who can always meet your delivery expectations.

Customer reviews and Testimonials

The views and experiences of the current customers should be the prime consideration in choosing a hot melt adhesive supplier. Testimonials or opinions from past clients who have used their services may have insightful information regarding the adequacy, reliability, and general satisfaction of the company.

You can find more information about the supplier’s capability and customer service approach by reading online reviews, industry forums, and customer references. Look for those with a history of good feedback toward them that reflects their overall level of service, responsiveness to client requests, and product quality.

Consider speaking to the supplier’s customers directly, in addition to reading online reviews. Question them on the adhesives’ quality, how good the technical support was and how straightforward or difficult it is to do business with them in terms of their experience of working with the supplier. This can hopefully give you a better view of what the supplier can do and how they could well meet your specific needs for packaging.

For example, common recurring patterns or themes may emerge as each customer gives his or her review, whether positive or negative. You can use this kind of data to determine if a supplier would be a good fit for your company by identifying where the supplier excels and perhaps where they fall short.

You are able to get quite an idea about the performance, reliability, and the service a supplier can provide through reading reviews and comments from past clients very carefully. Among these, some of the aspects can be very relevant when deciding on the best supplier for hot melt adhesives in your packaging needs.

Reflecting on the points covered

Choosing the best hot melt adhesive supplier is one of the crucial decisions you can make, and it just might make all the difference between maintaining productivity and achieving success with packaging operations. To determine potential suppliers and select a partner that meets your special needs and corporate objectives, consider the following factors presented in this article.

Remember, quality and dependability on the part of the adhesive supplier are as important because adhesives do affect the integrity of your packaging and its overall performance. Select a provider with excellent customer service, consistent performance, and quality goods.

Other than these factors, think about the range of adhesive products the supplier offers, the degree of customization, and the quality of technical support. A supplier who can provide a varied combination of adhesives and customized solutions will help you streamline your processes while solving certain specific problems with your packaging.

Conclusion

Determination of the Price and Value for Money: Balancing Performance and Quality/Price with Financial Considerations The next important consideration in contracting would be to evaluate price and value for money in the attempt to balance performance and quality/price with financial considerations. Try finding a supplier who can provide lower prices without compromising the quality of the delivered goods or services.

Then, do not forget to scan client testimonials and comments for the purpose of gathering relevant information on the reputation, credibility, and satisfaction by the provider. It will help you make a better-informed choice, therefore ensure that you work with a hot melt adhesive supplier who can find ways to dependably meet your packaging needs.

You can invest in the best quality for your packaging processes, improve your productivity, and give your customers better products when you take time to consider and choose the best supplier of hot melt adhesives. It will come with success in packaging once you have realized investing some time to select a reliable and trustworthy partner.

Before moving ahead, want to understand what hot melt adhesives are?

Read here!- https://superbond.co.in/hot-melts-adhesives/