Hot melt adhesives (HMAs) have become indispensable in today’s fast-paced manufacturing landscape, delivering instant, solvent-free bonds that streamline operations and promote sustainability. From high-speed packaging lines to precision woodworking, these versatile thermoplastics heated to a molten state and cooling into durable holds outpace traditional glues in speed and strength.

At Superbond Adhesives, our hot melt formulations set the standard with superior adhesion and heat resistance, empowering businesses in India and beyond to achieve unmatched efficiency since 1974. Discover how Superbond’s hot melt adhesives can transform your projects in the sections below.

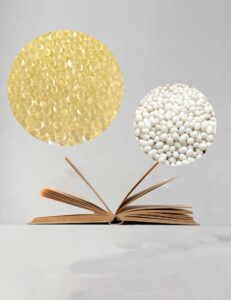

What are Hot Melt Adhesives?

Hot melt adhesives (HMAs), often referred to as hot glue, are thermoplastic polymers that start as solid sticks or granules and are heated to a molten state for application. Once applied, they cool and solidify rapidly to form a strong, flexible bond without the need for solvents or water, making them an eco-friendly and efficient choice for various industries. These adhesives excel in providing quick-setting times, high bond strength, and versatility across substrates like paper, plastic, wood, and metal, which is why they’re widely used in packaging, assembly, and crafting.

At Superbond Adhesives, our hot melt formulations, such as the Super Melt series, take this technology to the next level with enhanced temperature resistance and superior adhesion, ensuring reliable performance even in demanding production environments. Whether you’re sealing cartons or binding books, Superbond’s hot melts deliver consistent results that boost efficiency and durability.

Applications of Superbond Hot Melt Adhesives

Superbond Hot Melt Adhesives are engineered for a wide array of industrial uses, offering fast-setting, solvent-free bonding solutions that enhance productivity across sectors.

In packaging, they provide robust seals for cartons and trays. For book-binding, they ensure durable spine attachments and flexible page holds. In paper bag manufacturing, they enable efficient side and bottom seaming. Soap wrapper manufacturing benefits from their moisture-resistant seals on delicate films. Woodworking adhesives support edge banding and joint assembly with strong, quick bonds. Hot melt pressure sensitive adhesives (HMPSA) offer instant tack for labels and tapes. Jelly adhesives mimic traditional animal glues for woodworking and crafts with modern reliability. Glue stick adhesives simplify crafting and light assembly tasks. Finally, in courier adhesives, they secure poly mailers for tamper-proof shipping.

Applications of Superbond Hot Melt Adhesives in Packaging

Superbond’s packaging hot melt adhesive are tailored for high-speed packaging lines, delivering exceptional bond strength and compatibility with automated equipment. Here are key applications in the packaging industry:

-

Carton Sealing

Due to quick set times and strong adhesion Superbond hot melt adhesives are ideal for high speed lines and ensuring durable bonds under demanding conditions.

-

Case Sealing

Our hot melt adhesives provide reliable performance for case sealing, creating secure bonds across various packaging scenarios to maintain product integrity during transport.

-

Tray Forming

Hot Melt adhesives are utilized in tray forming, offering efficient adhesion that supports rapid production while delivering consistent strength for stable packaging structures.

-

Cushioning for Fragile Items

Hot Melt Adhesives are utilised in bonding foam to other materials such as wood or metal for cushioning and protection.

-

Courier Bag Manufacturing

Hot Melt adhesives are used in courier bag sealing ensuring the contents remain safe and prevents tampering. The adhesive is applied at the folds or edges by heat sealing the sides.

-

Wrappers

Hot melt adhesives are used in a variety of wrapper materials ensuring secure packaging along with heat and moisture resistance. The adhesive is applied to specific areas of the wrapper to create necessary seals and closures.

Applications of Superbond Hot Melt Adhesives in Book Binding Projects

Superbond hot melt adhesives revolutionize book binding by providing flexible, durable bonds that withstand repeated use. Their quick-setting properties accelerate production without sacrificing quality. Key applications include:

- Book Cover Bonding: Used to bond book covers made of cloth, leather, or paper to the spine, ensuring a durable and flexible finish.

- Page and Endpaper Attachment: Ideal for binding inner pages together and attaching endpapers or flyleaves securely to the book cover.

- Specialized Binding and Packaging Support: Suitable for bonding non-porous materials like plastic or metal in bookbanding applications and attaching foam packaging materials for added cushioning and protection during shipping.

Applications of Superbond Hot Melt Adhesives in Paper Bag Manufacturing

In paper bag production, Superbond industrial hot melt glue ensures strong, flexible seals that handle everyday stresses like folding and carrying. Their heat resistance makes them suitable for both retail and industrial bags. Notable uses are:

- Sealing Flaps and Seams: Superbond Hot Melt Adhesives are applied to the flaps and seams of paper bags to ensure strong, durable seals that hold the bag’s structure firmly in place.

- Edge Bonding: The adhesive is used along the edges to reinforce joints and prevent the bag from tearing or coming apart during handling and use.

- Structural Assembly: Ideal for bonding folded and creased paper sections, the adhesive ensures the overall shape and integrity of the bag are maintained throughout production and use.

Applications of Superbond Hot Melt Adhesives in Wood Working

Superbond’s hot glue for woodworking provides rapid, robust bonds in woodworking, ideal for furniture and cabinetry where speed and strength are essential. They’re non-toxic and easy to clean suitable for different industrial applications. Key uses are:

- Furniture Assembly: Used for bonding components such as chair frames, tabletops, and cabinet structures, ensuring strong and durable joints.

- Marine and Instrument Manufacturing: Ideal for bonding wood components in boats, musical instruments, and wooden toys, providing moisture-resistant and reliable adhesion.

- Interior Applications: Applied for joining carved wooden pieces, attaching wood paneling to walls, and securing wood flooring planks to subfloors, ensuring long-lasting structural stability.

Applications of Superbond HMPSA

Hot Melt Pressure Sensitive Adhesives (HMPSA) from Superbond offer instant tack and repositionability, thriving in dynamic bonding scenarios. Their thermal stability suits extreme conditions. Primary applications are:

- Hygiene Products: In sanitary napkins, diapers, and incontinence items, Superbond HMPSA ensures skin-safe, flexible bonds for comfort and leak prevention during wear.

- Automotive Assembly: Provides durable adhesion on plastics, metals, and fabrics in vehicle interiors, with instant tack speeding up line assembly without residue.

- Packaging Seals and Bottle Labels: Used for reclosable bags and labels, offering strong peel strength and compatibility with high-speed machines for efficient, clean removals.

- Medical Tapes: Bonds securely in bandages and dressings, resisting moisture and stress while remaining gentle on skin for reliable healing support.

Applications of Superbond Hot Melt Adhesives in Jelly/Animal Glue

Superbond’s jelly and animal glue-inspired hot melts replicate traditional warmth with modern efficiency, offering tacky, versatile bonds for crafts and assembly. They’re low-odor and heat-stable. Detailed uses include:

- Craftsmen trust jelly glue for its strong, precise bonds in woodworking, using it in joinery, veneering, and furniture assembly.

- Jelly glue is used to construct and repair string instruments such as violins, guitars, and cellos.

- Due to its authentic composition and reversible bonds, animal glue is used to restore and preserve artworks, antiques, and historical artifacts.

Conclusion

In summary, hot melt adhesives represent a cornerstone of modern industrial efficiency, offering solvent-free, rapid-bonding solutions that transform everything from everyday packaging to intricate woodworking and bookbinding projects. Superbond’s innovative lineup, including the Super Melt series, HMPSAs, and specialized formulations like jelly glues, stands out for its unmatched versatility, temperature resilience, and eco-conscious design, delivering bonds that not only hold strong but also adapt to the demands of high-speed production and sustainable practices.

As industries evolve toward faster, greener operations, Superbond Hot Melt Adhesives emerge as a reliable partner, reducing waste, enhancing durability, and streamlining workflows across sectors. Whether you’re a manufacturer scaling up packaging lines or a craftsman restoring heirlooms, these adhesives provide the precision and performance needed to stay ahead.